ProfiMessage devices have been specially developed for use as modular measurement, control and monitoring units. ProfiMessage uses a master/slave concept and has a range of I/O modules to meet the requirements of any system. This enables the problem-free functioning of multi-channel systems.

Modular measurement data acquisition and monitoring

ProfiMessage devices have universal connectivity to any process. They also have flexible I/O modules and a diverse range of field bus interfaces. ProfiMessage is extremely easy to connect to PLC control systems to perform data exchange. All measurement data is recorded at high temporal resolution.ProfiMessage has integrated control, calculation and monitoring functions which make it the ideal combination device. Measurement data can be simultaneously acquired and monitored with control and regulation tasks being independently processed.

ProfiMessage devices for independent measurement and recording. An internal 16 GB data memory is able to record several billion measurement values. At the click of a button the data can be transferred to a USB stick and evaluated offline. Data read outs can also take place online via an Ethernet interface. These can be performed manually or automatically according to a time plan. ProfiMessage is ideal for fast, precise and galvanically isolated measurement data, as well as for intelligent pre-processing and monitoring. Applications range from the monitoring and observation of industrial processes and machinery through to vibration measurement technology.

In conjunction with the AMDT I/O vibration module, ProfiMessage can be used to process shaft and bearing vibrations. The devices are then typically used in condition monitoring systems as monitoring and analysis units.

By connecting the device to a modem enables fully independent operation for remote monitoring of equipment, ships, vehicles or any other decentralized machinery.

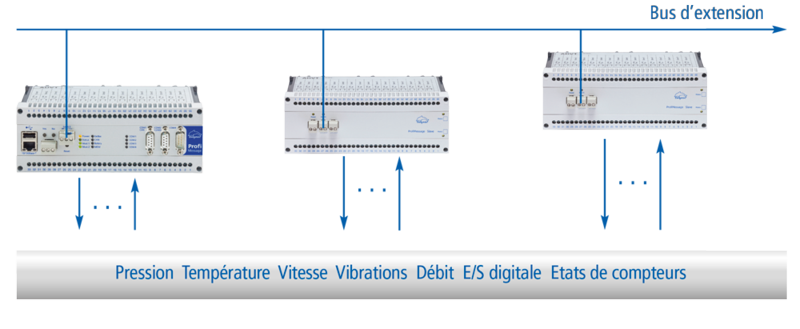

Flexible extendibility

ProfiMessage master and slave devices can be equipped with two identical or differing I/O modules. A single master device can be connected with up to 20 slave devices of similar casing designs.

Data exchange between master and slaves takes place via a real time expansion bus using robust dual-wire technology. Slave devices can be decentrally located and managed from a single master device.

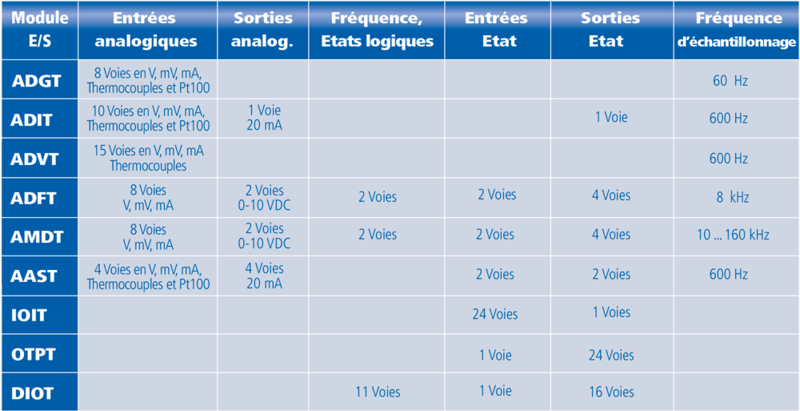

Nine different I/O modules are available for ProfiMessage. Each master or slave device can be equipped with two either identical or differing I/O modules.

For processing only field bus signals, master devices can be supplied without any I/O modules. ProfiMessage then functions as a PLC data logger for process fault detection and diagnostics.