| Expert Logger 100 | 16 Analog Inputs (mV/mA/Thermocouple), 1 KS/s, 4 DI, 4 DO, 4 DIO, 1 SensorBus | |

| Expert Logger 200 | 32 Analog Inputs (mV/mA/Thermocouple), 2 Ke/s, 4 DI, 4 DO, 4 DIO, 1 SensorBus | |

| Expert Logger 300 | 46 Analog Inputs (mV/mA/Thermocouple), 3 Ke/s, 1 DI, 1 DO | |

| Expert Logger 400 | 16 Analog Inputs (mV/mA/Thermocouple), 1 Ke/s, 1 DI, 24 DIO, 6 Analog Outputs |

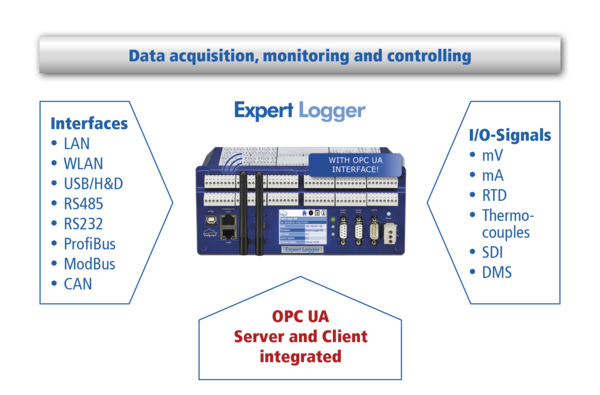

Expert Logger - Stand alone data logger

- Universal analog inputs (mV, mA, TC, RTD)

- SDI12 interfaces for environmental sensors

- Independent operation possible with batteries or rechargeables

- Minimal energy consumption via a sleep function

- 2 .. 14 GB of internal data storage for up to 125 million measurement values

- PUSH function to send measurement data to the internet

- WLAN link to PCs and mobile devices

- LAN and USB interface to a PC or network

- Monitoring and data logging in a single device

Expert Logger is a new generation of data loggers. It combines the latest communication technology with advanced measurement technology, and is based on FPGA technology to make it especially powerful. It can process up to 46 analog input channels at both low and high rates of sampling. Measurement data can be accurately acquired, independently stored and transmitted to the internet or a PC for evaluation via USB, LAN, WLAN or LTE.

OPC UA is becoming an increasingly established protocol and when used with the Expert Logger devices, measurement acquisition, monitoring and test stand automation applications can be made ready for open data exchange data in accordance with Industry 4.0/Internt of Things.

Both OPC UA servers and clients have been integrated into the Expert Logger devices to enable fast, easy and barrier-free data exchange with sensors and sub-systems also supporting OPC UA.

Many products such as frequency converters, controllers and regulators have already fully integrated OPC UA. The opportunities provided by OPC UA have been identified within the measurement and sensor technology sector with several sensors and actuators now available with OPC UA interfaces.

In addition to OPC UA, Expert Logger devices are also equipped with PROFIBUS, ModBus, CAN-Bus and serial interfaces for sensor and field level connections.

Operation made simple

Sensors are connected via plug-in screw terminals and a chart clearly shows how channels are arranged. Users always have a good overview of the channels despite their high density. Each set of four terminals can be configured as two differential inputs to measure voltage, currents, thermocouples, or to take measurements from a 4-wire RTD.

Configuration – fast and easy

The Expert Logger is simple to configure from a PC. These settings remain stored within the Expert Logger even when disconnected from the power supply. The device settings can also be read out and stored on a PC and analysed offline without the need for a connected Expert Logger. The offline configuration settings are then simply read into the device when connected. The software used for configuration is simple to operate to let users fully focus on their measurement tasks.

Intelligent signal processing

Signal processing using internal software channels significantly simplifies measurement tasks. Flexible calculation channels enable measurement data to undergo further computation and recording. Integrators directly calculate volumes or quantities from time related measurement data such as mass and discharge flow rates. Limit values can monitor measurement data and be used to switch digital outputs or automatically send emails. Complex signal processing is possible using pulse counters, stop-clock functions and operating-hours counter. Averages can be calculated and recorded as time-weighted or moving. The Expert Logger‘s software channels clearly set it apart from other loggers and make it very popular among users.

- Data logging

- Environmental measurement technology

- Product testing

- Measurement data diagnosis

- Lab data acquisition

- Trials and tests

- Energy optimization